High-Performance Raw Materials for GRC Manufacturers

Supplier of premium glass fibres, polymers and nano‑modified titanium dioxide tailored to the requirements of professional GRC manufacturers. The product portfolio is sourced exclusively from leading global producers, ensuring consistent quality, reliable performance and full traceability for demanding GRC applications.

With extensive hands‑on experience in GRC manufacturing, the service focuses on practical solutions that improve mix design, durability and surface quality. In‑depth technical understanding of moulding, spraying, casting, compacting, handling, curing, de‑moulding, repairing, storing and delivering enables tailored recommendations that support both small workshops and large industrial plants.

The glass fibre range is engineered for optimal reinforcement, crack control and long‑term strength. Complementary polymer solutions act as curing agents that improve workability, adhesion and weather resistance, while nano‑modified titanium dioxide contributes to self‑cleaning surfaces, colour stability and superior aesthetics in architectural GRC elements.

Support includes material selection, dosage optimisation and troubleshooting of common GRC production challenges. The objective is to help manufacturers achieve consistent, high‑quality output while reducing waste and production downtime.

For more information about products and services, further details are available on this site.

LinkedIn (13) Simon Hertzum | LinkedIn

Key Partners

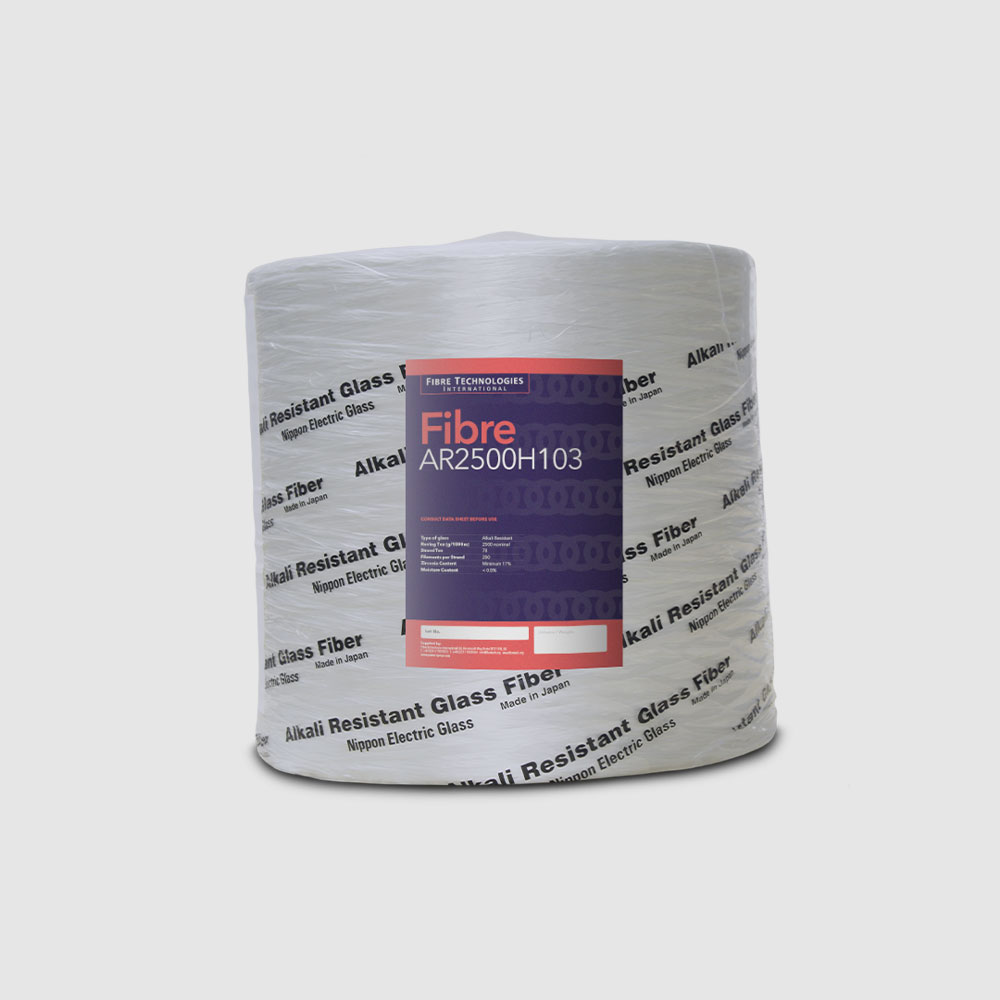

— Fibre Technologies

Key Partner for Polymers and Fibres

Fibre Technologies is a trusted partner for advanced polymers and fibres, supporting innovation from concept to commercialisation. With deep expertise in fibre science, polymer engineering and process optimisation, the company helps organisations develop high‑performance materials tailored to demanding industrial applications.

As an independent technology specialist, Fibre Technologies focuses on delivering practical, scalable solutions. Services span material selection, formulation, fibre development and performance testing, ensuring that every project is guided by robust data and industry best practice.

Collaboration is at the heart of every engagement. Fibre Technologies works closely with manufacturers, brand owners and research organisations to accelerate development cycles, reduce risk and unlock new opportunities in technical textiles, composites and sustainable materials.

From feasibility studies to full‑scale implementation, Fibre Technologies combines scientific insight with real‑world manufacturing experience. This integrated approach makes the company a key partner for businesses seeking reliable support in polymers, fibres and related technologies.

More information about the company, its capabilities and project examples is available on the official Fibre Technologies about page.

— Photocat

Self-Cleansing and NOx-Reducing Modified Titanium Dioxide

Self-cleansing and NOx-reducing modified titanium dioxide is an advanced photocatalytic material designed to improve air quality and keep surfaces cleaner for longer. When activated by light, this innovative form of titanium dioxide helps break down harmful nitrogen oxides (NOx) and organic pollutants, supporting cleaner environments in urban and industrial areas.

A key partner in the development and commercialization of these photocatalytic solutions is Photocat. The company focuses on high-performance materials that can be integrated into coatings, construction products, and other surface treatments to deliver long-lasting environmental benefits. By combining modified titanium dioxide with proven application technologies, Photocat enables surfaces that actively contribute to air purification and reduced maintenance needs.

Photocat’s solutions are used in a variety of applications, including building facades, pavements, and other infrastructure where air pollution and dirt accumulation are major challenges. The technology supports sustainable construction, improved urban air quality, and reduced cleaning costs over the lifetime of the treated surfaces.

Read more about Photocat and its photocatalytic technologies on the official website: Photocat.

Contact

Contact is always open and welcome.

Relationships are between people, and as a true people person the relationship is always more important than any short-term gain. Words matter, promises matter, and every agreement should be something that can be relied on without doubt.

Trust is built when a word can be trusted and actions match what has been said. When an agreement is questioned, honesty must move to the forefront so that clarity, respect, and mutual understanding can be restored.

Every contact is treated with sincerity, transparency, and a genuine focus on rebuilding and strengthening the relationship. The goal is always a respectful, honest connection where both sides feel heard, valued, and taken seriously.

- Clear and honest communication

- Respect for every agreement

- Focus on long-term relationships

- Trust built through consistent actions

Contact details

simonsaysgrc.com

Skovvaenget 16, 4600 Koege

+45 26802323

simon.hertzum@gmail.com

About

With more than 12 years of dedicated experience in the glassfibre reinforced concrete (GRC/GFRC) and façade industry, this professional has played a key role as part owner of a large international manufacturing company, delivering award‑winning and renowned façade projects across multiple markets.

Former Chairman of the Council of the GRCA (the international Glassfibre Reinforced Concrete Association) and current Director of the association, this background combines hands‑on technical expertise with strategic leadership at the highest industry level.

Extensive project involvement ranges from complex bespoke façades to large‑scale commercial developments. Collaboration with architects, engineers and contractors ensures that each façade system meets demanding aesthetic, structural and sustainability requirements.

Through ongoing work with the GRCA and continuous engagement with international standards and best practices, this experience contributes to raising the profile of GRC worldwide and supporting clients seeking reliable, technically advanced façade solutions.

Professional Profile in Manufacturing and Industrial Management

Responsibility, critical thinking and practical experience and a strong understanding of how theoretical concepts translate into real-world production enables effective decision-making on the shop floor and in strategic planning.

This profile is defined by the ability to bridge the gap between engineering theory, process design and the daily realities of manufacturing. It includes a clear awareness of end client demands and how these requirements influence every stage of production, from planning and procurement to assembly and final delivery.

There is a deep appreciation of the constant pressure on manufacturers, where time, quality and cost often pull in different directions. Balancing tight deadlines, strict quality standards and budget constraints is approached with structured analysis, prioritisation and continuous improvement methods.

Through hands-on experience and critical reflection, this profile supports organisations in optimising processes, reducing waste and aligning production outcomes with customer expectations and long-term business goals.

Long-Term Business Relationships

Long-term business relationships are built on trust, transparency, and mutual respect. Every collaboration is guided by the principle that sustainable success comes from investing time, attention, and genuine care in each partnership. The focus is always on creating value that lasts, rather than seeking short-term gains.

The relationship is first and foremost with the people who work within each company. Every agreement is considered personal and is treated with discretion, integrity, and professionalism. Communication is open and honest, ensuring that expectations are clear and that all parties feel heard and respected throughout the process.

By prioritizing people over transactions, each partnership becomes more than a contract. It becomes a shared commitment to growth, reliability, and long-term collaboration. This approach fosters loyalty, strengthens cooperation, and creates a solid foundation for future opportunities and continued success.

Work Experience

CEO and Co‑Owner of BB Fiberbeton A/S Group

From primo 2014 to ultimo 2025, the role as CEO and co‑owner of BB Fiberbeton A/S Group is defined by a clear transformation journey: from a small‑scale trades firm with only a few dedicated employees to a modern industrial company with scalable processes and international ambitions.

The period is characterized by strategic restructuring, professionalization of management, and continuous investment in technology and people. Focus areas include optimization of production, implementation of standardized workflows, and development of a strong safety and quality culture that supports long‑term growth.

Under this leadership, BB Fiberbeton A/S Group evolves from project‑driven craftsmanship to an industrial setup with higher capacity, improved delivery reliability, and stronger competitiveness. The company strengthens its position in the market for GRC solutions and builds long‑term partnerships with architects, contractors, and industrial clients.

The journey from small trades firm to industrial company reflects a clear vision: to combine craftsmanship and innovation in GRC with efficient industrial production, creating sustainable and aesthetically strong solutions for modern construction.

— Education

Copenhagen University

Master degree in Law, 2006

Contact